Replacing Manpower With Machines to Promote Traditional Production

- Categories:2021

- Author:

- Origin:

- Time of issue:2021-10-14 12:02

- Views:0

Replacing Manpower With Machines to Promote Traditional Production

(Summary description)Since 2014, our company has spent 400 million yuan to construct the III phase of DTY spinning project. We continue to carry out digital transformation of the whole production process to improve the quality and increase the efficiency of traditional textile and chemical fiber production.

Now, AGV(Automatic Guided Vehicle)under the control of the industrial Internet platform, can send products to the production line, in the artificial intelligence machine can pack them automatically.

Through digital transformation, our production process from the original basically rely on manual operations to intelligent operations. Including digital inspection, integrated inspection, automatic packaging, greatly improve the production efficiency.

Up to now, the phase III has introduced 36 sets of advanced digital production equipment from Germany, which can produce 30 tons of high quality nylon 6 products every day. Only one link of packaging, before needs 15 skilled workers, after the digital transformation, only 8 operators are needed, the efficiency has been improved by more than 40%.

Next year, we plan to import another 12 sets of German Bamag digital production equipment. We will continue to replace manpower with machines to promote the development of traditional textile and chemical fiber production.

- Categories:2021

- Author:

- Origin:

- Time of issue:2021-10-14 12:02

- Views:0

Since 2014, our company has spent 400 million yuan to construct the III phase of DTY spinning project. We continue to carry out digital transformation of the whole production process to improve the quality and increase the efficiency of traditional textile and chemical fiber production.

Now, AGV(Automatic Guided Vehicle)under the control of the industrial Internet platform, can send products to the production line, in the artificial intelligence machine can pack them automatically.

Through digital transformation, our production process from the original basically rely on manual operations to intelligent operations. Including digital inspection, integrated inspection, automatic packaging, greatly improve the production efficiency.

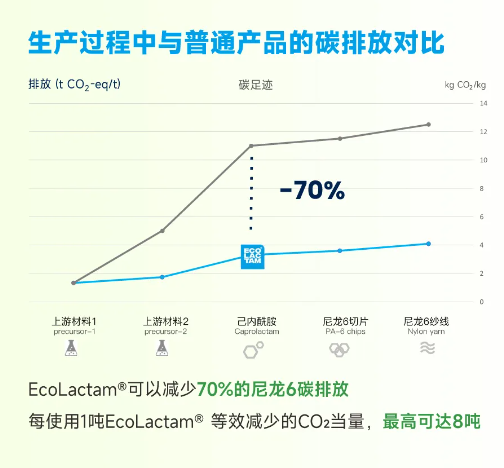

Up to now, the phase III has introduced 36 sets of advanced digital production equipment from Germany, which can produce 30 tons of high quality nylon 6 products every day. Only one link of packaging, before needs 15 skilled workers, after the digital transformation, only 8 operators are needed, the efficiency has been improved by more than 40%.

Next year, we plan to import another 12 sets of German Bamag digital production equipment. We will continue to replace manpower with machines to promote the development of traditional textile and chemical fiber production.

LINKS