HSCC Won Two May 1 Labor Honors

- Categories:News Center

- Author:恒申集团

- Origin:

- Time of issue:2021-04-22 14:27

- Views:0

HSCC Won Two May 1 Labor Honors

(Summary description)After the public announcement of the candidates (collective) for the National May Day Labor Award and the National Workers Pioneer in 2021, Chance Liheng Polyamide Technology Co., Ltd (LHP). under HSCC was awarded the "National May Day Labor Award in 2021".

Chen Lijun of HSCC R&D Center was awarded "2021 Fujian Provincial May Day Labor Medal" by Fujian Federation of Trade Unions.

LHP is the HSCC set nylon research and development, production, sales as one of the high-tech enterprises. Over the years, LHP deep cultivation of the nylon market, in 2009 set up a provincial enterprise technology center, constantly improve the application ability of innovative technology in production, annual output value of more than 8 billion yuan.

With high technology as the starting point, technology as the core and strong technical team as the support, the company has established "Expert Workstation" and "Fujian Enterprise Technology Center", and won wide recognition from the society by virtue of high quality products and perfect services.

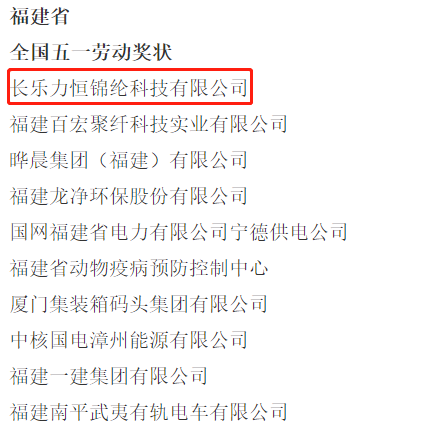

Chen Lijun senior engineer, over the years focused on nylon 6 research and development work, led the R&D team has repeatedly break the monopoly of foreign technology, was awarded scientific and technological progress first prize of China's textile industry association, led the team to get breakthrough in the field of technology at the same time. He personally has become the industry standard type, in the development of domestic nylon industry plays an important role in the process.

Chen Lijun is responsible for the project of "High-capacity Polyamide 6 Polymerization and Polyamide 6 Fully Drawn Porous Fine denier Fiber Manufacturing Key Technology and Equipment", which has developed the manufacturing technology of the finest polyamide filament in China. The length of the filament can reach 450 kilometers per gram.It has become the first project in China to put high-capacity polyamide 6 polymerization technology into production, and LHP has become the first company in China to produce full dull polyamide 6 chips. This project breaks the foreign technology monopoly, fills the domestic technology gap, and becomes a milestone event in the development process of textile industry.

In addition, Chen Lijun led the technical team of the company to improve the nylon spinning process and enhance the production capacity of the group; We have developed many high-performance products, including recycled nylon, dope dyed nylon, graphene nylon, collagen nylon, high tenacity nylon, etc. These functional yarns have good performance and multiple composite functions, which are well recognized by the market, laying a foundation for HSCC to obtain the leading position in the industry.

LHP and Chen Lijun were respectively awarded the "National May Day Labor Medal in 2021" and "Fujian May Day Labor Medal in 2021", which is the affirmation of the hard work of all the workers in the company. Both the grass-roots staff and the management staff are responsible and selfless in the high-quality development of the country and Fujian Province.

HSCC will take this as an advanced demonstration, further encourage the group staff to carry forward the spirit of model workers, the spirit of craftsmen, work hard and work steadfast, and jointly write a new chapter of the "14th Five-Year" construction and development.

- Categories:News Center

- Author:恒申集团

- Origin:

- Time of issue:2021-04-22 14:27

- Views:0

After the public announcement of the candidates (collective) for the National May Day Labor Award and the National Workers Pioneer in 2021, Chance Liheng Polyamide Technology Co., Ltd (LHP). under HSCC was awarded the "National May Day Labor Award in 2021".

Chen Lijun of HSCC R&D Center was awarded "2021 Fujian Provincial May Day Labor Medal" by Fujian Federation of Trade Unions.

LHP is the HSCC set nylon research and development, production, sales as one of the high-tech enterprises. Over the years, LHP deep cultivation of the nylon market, in 2009 set up a provincial enterprise technology center, constantly improve the application ability of innovative technology in production, annual output value of more than 8 billion yuan.

With high technology as the starting point, technology as the core and strong technical team as the support, the company has established "Expert Workstation" and "Fujian Enterprise Technology Center", and won wide recognition from the society by virtue of high quality products and perfect services.

Chen Lijun senior engineer, over the years focused on nylon 6 research and development work, led the R&D team has repeatedly break the monopoly of foreign technology, was awarded scientific and technological progress first prize of China's textile industry association, led the team to get breakthrough in the field of technology at the same time. He personally has become the industry standard type, in the development of domestic nylon industry plays an important role in the process.

Chen Lijun is responsible for the project of "High-capacity Polyamide 6 Polymerization and Polyamide 6 Fully Drawn Porous Fine denier Fiber Manufacturing Key Technology and Equipment", which has developed the manufacturing technology of the finest polyamide filament in China. The length of the filament can reach 450 kilometers per gram.It has become the first project in China to put high-capacity polyamide 6 polymerization technology into production, and LHP has become the first company in China to produce full dull polyamide 6 chips. This project breaks the foreign technology monopoly, fills the domestic technology gap, and becomes a milestone event in the development process of textile industry.

In addition, Chen Lijun led the technical team of the company to improve the nylon spinning process and enhance the production capacity of the group; We have developed many high-performance products, including recycled nylon, dope dyed nylon, graphene nylon, collagen nylon, high tenacity nylon, etc. These functional yarns have good performance and multiple composite functions, which are well recognized by the market, laying a foundation for HSCC to obtain the leading position in the industry.

LHP and Chen Lijun were respectively awarded the "National May Day Labor Medal in 2021" and "Fujian May Day Labor Medal in 2021", which is the affirmation of the hard work of all the workers in the company. Both the grass-roots staff and the management staff are responsible and selfless in the high-quality development of the country and Fujian Province.

HSCC will take this as an advanced demonstration, further encourage the group staff to carry forward the spirit of model workers, the spirit of craftsmen, work hard and work steadfast, and jointly write a new chapter of the "14th Five-Year" construction and development.

LINKS